VÄDERSTAD TEMPO L™

Pneumatic precision planters with rows between 8 and 24

Every component on the Tempo planter is built to ensure the exact same start for all seeds. No matter the speed – no matter the field condition. The even seed placement results in a crop that matures at an even rate and is more likely to yield to full potential.

The Tempo planter delivers an exact seed spacing, even seed depth and no overlap planting on headlands. On top of this, the planting precision is always the same irrespective of outside influences such as speed, vibrations, slopes or varying field conditions.

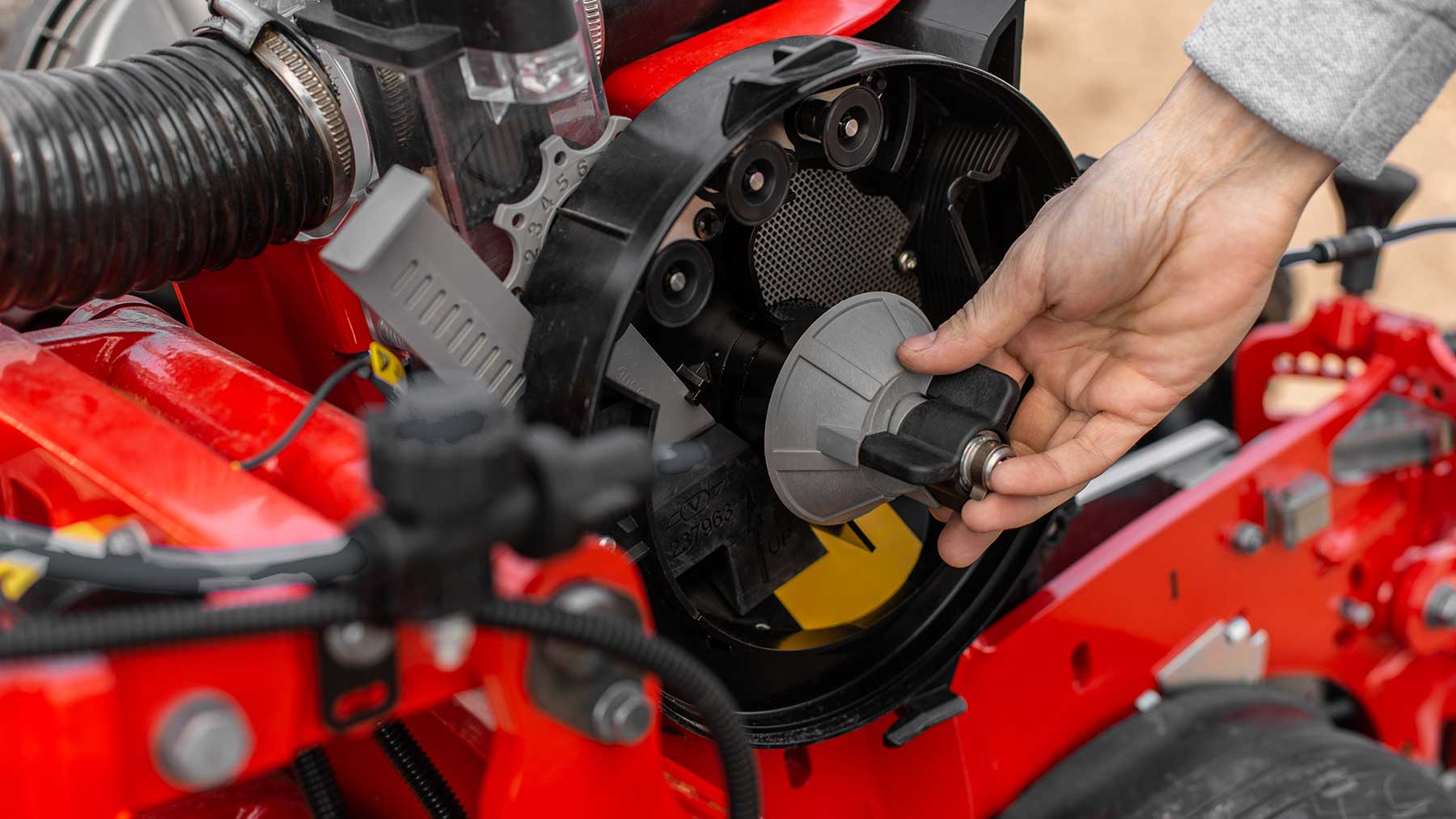

The Tempo seed meter stands out from the crowd. Thanks to the Power Shoot technology, which uses air pressure to maintain full control of the seed all the way down to the soil; gravity, vibrations and slopes are removed from the equation. Speed is not an issue for Tempo.

Tempo takes modern technology to the field. Each Tempo row unit is individually electric driven and the control system Väderstad E-Control seamlessly establishes a real time communication between the planter, the tractor and you as a driver. The planter electronics constantly ensures performance and you benefit from user-friendly remote setup, as well as real-time monitoring and full control.

The Tempo planter delivers an exact seed spacing, even seed depth and no overlap planting on headlands. On top of this, the planting precision is always the same irrespective of outside influences such as speed, vibrations, slopes or varying field conditions.

The Tempo seed meter stands out from the crowd. Thanks to the Power Shoot technology, which uses air pressure to maintain full control of the seed all the way down to the soil; gravity, vibrations and slopes are removed from the equation. Speed is not an issue for Tempo.

Tempo takes modern technology to the field. Each Tempo row unit is individually electric driven and the control system Väderstad E-Control seamlessly establishes a real time communication between the planter, the tractor and you as a driver. The planter electronics constantly ensures performance and you benefit from user-friendly remote setup, as well as real-time monitoring and full control.

Tempo L 8-24

Tempo L is a trailed high-speed planter with an enormous capacity. Tempo L doubles the capacity of a traditional planter. Most importantly, the crop is established with higher precision.

Tempo L can be equipped to place fertilizer together with planting. Depending on the model, either a 3000 or 5000 litre fertilizer hopper is available. The fertilizer is metered via the high capacity metering system, Fenix III. The metering capacity for fertilizer is up to 350kg/ha at 15km/h. The electric driven Fenix III has the capability to adapt the fertilizer rate to varying field conditions by using a variable rate system. The high capacity fertilizer system maintains the high precision even at high speed.

Perfect depth control

Tempo L is equipped with hydraulic wing pressure which transfers weight from the inner section of the machine to its outer wings. This enables Tempo L to respond to any irregularities on the field and ensure an even emergence.

Telescopic wheel axle

To ensure the transport wheels follow the row spacing, Tempo L can be fitted with a telescopic wheel axle which is easily adjusted from the cab. So whatever the row spacing, the transport wheels can be adjusted to always run between the seed rows. The wheel axles are easily set to 3 meters width for transport.

Tempo L can be equipped to place fertilizer together with planting. Depending on the model, either a 3000 or 5000 litre fertilizer hopper is available. The fertilizer is metered via the high capacity metering system, Fenix III. The metering capacity for fertilizer is up to 350kg/ha at 15km/h. The electric driven Fenix III has the capability to adapt the fertilizer rate to varying field conditions by using a variable rate system. The high capacity fertilizer system maintains the high precision even at high speed.

Perfect depth control

Tempo L is equipped with hydraulic wing pressure which transfers weight from the inner section of the machine to its outer wings. This enables Tempo L to respond to any irregularities on the field and ensure an even emergence.

Telescopic wheel axle

To ensure the transport wheels follow the row spacing, Tempo L can be fitted with a telescopic wheel axle which is easily adjusted from the cab. So whatever the row spacing, the transport wheels can be adjusted to always run between the seed rows. The wheel axles are easily set to 3 meters width for transport.

The key for high-speed planting

The patented Power Shoot system makes the Tempo stand out from the crowd. On classic seeders, the seeds fall freely through the sowing tube from the dispenser to the ground. When vibrations occur at higher speeds, the seeds jump into the tubes and much of the accuracy is lost here. This is one of the reasons why many drills are limited to low seeding speeds. Power Shoot uses air pressure to shoot seeds at 50 km/h through the short seed tube into the soil. Thus the Tempo seeder has absolute control of each seed, from the hopper to the ground.

Accuracy in line

The Tempo dispenser together with the PowerShoot technology guarantees the precise placement of the seeds one by one in the furrow. By ensuring uniform distances between plants, without double sowing or misses, Tempo ensures high sowing precision. This means that all plants have insurance

the same germination conditions from the beginning.

Depth accuracy

The Tempo planter has a robust construction, transferring substantial weights to the sowing rows. Together with its components, it ensures a stable movement while maintaining the sowing depth in all conditions. High precision leads to uniform germination, which transforms

in strong growth of strong and healthy crops with high potential.

Precision at the top of the line

Each individual row of the Tempo is electrically driven, allowing GPS control of individual section closures. By eliminating overlaps

on heads and irregular terrain, possible losses are thus eliminated while reducing set-up costs by 5% to 10%. Tempo

can control individual sections for seed, fertilizer and microgranules.

Accuracy in line

The Tempo dispenser together with the PowerShoot technology guarantees the precise placement of the seeds one by one in the furrow. By ensuring uniform distances between plants, without double sowing or misses, Tempo ensures high sowing precision. This means that all plants have insurance

the same germination conditions from the beginning.

Depth accuracy

The Tempo planter has a robust construction, transferring substantial weights to the sowing rows. Together with its components, it ensures a stable movement while maintaining the sowing depth in all conditions. High precision leads to uniform germination, which transforms

in strong growth of strong and healthy crops with high potential.

Precision at the top of the line

Each individual row of the Tempo is electrically driven, allowing GPS control of individual section closures. By eliminating overlaps

on heads and irregular terrain, possible losses are thus eliminated while reducing set-up costs by 5% to 10%. Tempo

can control individual sections for seed, fertilizer and microgranules.

INDUSTRIES

SC Titan Machinery Romania SRL